Rubber Sheeting: Versatile, Durable, and Essential for Various Industries

Rubber sheeting is a versatile material used across various industries for its durability, flexibility, and resistance to extreme conditions. Whether you’re looking for Insertion Rubber Sheeting, Neoprene Rubber Sheeting, EPDM Rubber Sheeting, Anti-Static Rubber Sheeting, Nitrile Rubber Sheeting, or SRB Rubber Sheeting, this guide will provide you with everything you need to know. From its types and applications to its benefits, we’ll cover it all to help you make an informed decision.

What is Rubber Sheeting?

This Rubber is a highly durable and flexible material used across multiple industries for sealing, insulation, and protective applications. It comes in various formulations to meet specific needs, such as resistance to chemicals, oils, abrasion, and extreme temperatures. These Sheets are available in various thicknesses, widths, and surface finishes to suit sealing, insulation, cushioning, impact resistance, and protective purposes.

Types of Rubber Sheeting and Their Benefits

Insertion Rubber Sheeting: Reinforced for Strength

Insertion rubber is enhanced with fabric reinforcement, making it stronger and more resilient for heavy-duty applications. It is ideal for sealing, gasketing, and industrial linings where added strength is required.

Key Benefits:

- High tensile strength and durability

- Excellent abrasion and impact resistance

- Suitable for high-pressure environments

Neoprene Rubber Sheeting: Weather and Chemical Resistant

Neoprene rubber is a synthetic rubber known for its resistance to oils, chemicals, and harsh weather conditions. It is widely used in marine, automotive, and construction industries.

Key Benefits:

- Resistant to oil, ozone, and UV exposure

- Excellent thermal stability and flexibility

- Long-lasting performance in outdoor settings

EPDM Rubber Sheeting: Best for Outdoor Use

EPDM (Ethylene Propylene Diene Monomer)This rubber is a top choice for outdoor applications due to its superior resistance to weathering, UV rays, and ozone.

Key Benefits:

- Outstanding resistance to weather and chemicals

- Effective waterproofing material

- Retains flexibility in extreme temperatures

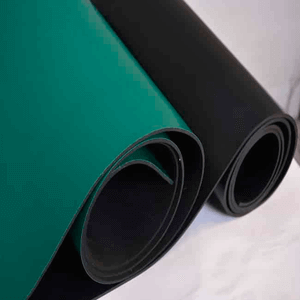

Anti-Static Rubber Sheeting: Essential for Electronics

Anti-static rubber is designed to dissipate static electricity, preventing electrostatic discharge (ESD) that can damage sensitive electronic equipment.

Key Benefits:

- Protects electronic components from static discharge

- Durable and non-conductive material

- Available in various thicknesses for different applications

Nitrile Rubber Sheeting: Best for Oil and Fuel Resistance

Nitrile rubber offers superior resistance to oils, fuels, and chemicals, making it an ideal choice for industrial, automotive, and aerospace applications.

Key Benefits:

- Exceptional oil, fuel, and chemical resistance

- High tensile strength and durability

- Ideal for gaskets, seals, and industrial machinery

SRB Rubber Sheeting: Cost-Effective and Reliable

SRB (Styrene Butadiene Rubber) sheeting is an economical alternative to natural rubber, offering good mechanical properties and wear resistance for various applications.

Key Benefits:

- Affordable yet durable option

- Excellent abrasion and wear resistance

- Versatile for general industrial use

Common Applications of Rubber Sheeting

Rubber serves a wide range of industries due to its adaptability and resilience. Some common uses include:

- Sealing & Gaskets: Used in automotive, aerospace, and industrial machinery.

- Industrial Flooring: Provides slip resistance and impact protection.

- Electrical Insulation: EPDM and anti-static rubber prevent electrical hazards.

- Marine Applications: Neoprene sheeting is ideal for waterproof seals and fendering.

- Food & Beverage Industry: Some rubber are used for hygienic purposes.

How to Choose the Right Rubber Sheeting

- Identify the Application

Determine the primary use of the rubber, such as sealing, insulation, or flooring. - Consider Environmental Factors

Evaluate the environmental conditions, such as temperature, exposure to chemicals, and UV radiation. - Check Material Properties

Choose a material that offers the necessary properties, such as flexibility, durability, and resistance to specific elements. - Consult with Experts

If you’re unsure, consult with a rubber supplier or manufacturer to get recommendations based on your needs.

Maintenance and Care of Rubber Sheeting

- Regular Cleaning

Clean the rubber sheeting regularly to remove dirt, debris, and chemicals that could degrade the material. - Inspect for Damage

Periodically inspect the sheeting for signs of wear, tear, or damage, and replace it if necessary. - Store Properly

When not in use, store rubber in a cool, dry place away from direct sunlight and harsh chemicals.

Why Invest in High-Quality Rubber Sheeting?

Choosing high-quality rubber ensures:

- Longer lifespan and reduced maintenance costs

- Improved safety and performance

- Compliance with industry standards

- Better protection for industrial equipment

By selecting the appropriate rubber for your needs and maintaining it properly, you can ensure optimal performance and longevity. If you’re looking for high-quality rubber, consult with a trusted supplier to find the best solution for your requirements.