Looking to enhance your workshop’s floors? Start with these steps to upgrade your South African workshop with practical and durable floors options.

- Explore Your Choices: Assess the variety of workshop floors available. Whether you seek durability for heavy-duty use or style to complement your workspace, we have you covered.

- Free Samples to Your Doorstep: Visualize how different textures and colors match your workshop by ordering free samples from local suppliers.

- Where to Shop?: Once you decide, purchase your new flooring from specialized online stores that provide detailed product insights, or visit local home improvement stores to see the materials firsthand. Watch for discounts to get the best deal!

By following these straightforward steps, you’re well on your way to transforming your workshop into a more functional and visually appealing space.

The right floor is the most important aspect in every workshop, be it large or small workshops this is where things get done. As workshops are different so are the flooring options depending on the nature of work done in the workshop.

In this article we will look at various types of workshop floorings:

Epoxy Flooring For Workshop

Epoxy floors is matched to meet a variety of factors, it is ideal for any manufacturing operations

Features of Epoxy Flooring

- Outstanding abrasion impact resistance

- Epoxy is very hard and cannot easily break or crack when hard things fall on them.

- Impressive compressive strength

- The level of strength the floor has is amazing it can withstand vibrating equipment.

- Resistant to chemicals, stains, and acids

- Epoxy matting is not easily affected by chemicals or even acids

- Slip-resistant for additional safety

- Epoxy floors increase traction making the flooring slip-resistant and safe to work on.

- Waterproof – Epoxy floors does not soak nor does not allow water from underneath to find its way onto the top floor.

- Crack repair and resurface option

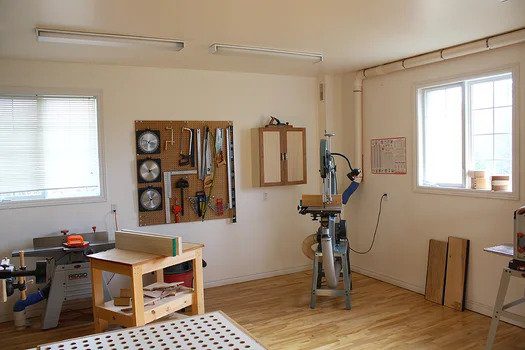

Wooden Flooring

Wooden flooring is an alternative workshop floors option, this type of flooring required hardwood. Wooden flooring is ideal for a workshop that is not characterized with usage and heavy equipment, ideal for a woodwork workshop and other light repairs and maintenance activities.

Features of Wooden Flooring

- The floors are made from hardwood

- Wood is not resistant to many chemicals and acid

- Not suitable for areas prone to moisture

- Moisture should not stay for a long time on the surface as it affects the flooring

- Moisture with time can find its way from the underneath subfloors and soak the flooring

- Tends to crack or break under heavy usage

- Though wooden flooring is fairly durable, it is not resistant to heavy impacts.

- Difficult to install

- Easy to clean and maintain

Concrete Floors

Concrete floors with smooth cement flooring is another popular floor option for workshops, especially in Africa. Concrete floors are very easy to install that why it is very popular in workshops, and is at the same fair versatile and can be used in many different types of workshops. Concrete floors can also be used as an underlayment for other types of floorings such as rubber and epoxy floors.

Features of Concrete Floors

- Large workshops sometimes coat the concrete flooring with epoxy

- Highly slip resistant

- Easy to clean and maintain

- Easy to install

- Hard surface

- A bad impact absorber

- Stressful on the feet is not a good anti-fatigue

- Durable and resilient

- Can withstand high traffic

- Fairly versatile can accommodate various types of workshops

Workshop Rubber Tiles

Rubber is an exciting workshop flooring and is ideal for various types of workshop activities such as repairs, maintenance, and manufacturing operations. Rubber tiles comes in different patterns. It is available as:

- Rubber interlocking tiles

- These interlocking tiles come with an interlocking system that makes them easy to install and provides more grip

- Rubber Rolls

- This type comes through as rubber sheets easy to install as well.

- Rubber mats are mainly just spread over an already exciting floor and are very good at protecting the subfloors from any floor damaging factors

Features of Workshop Rubber Tiles

- Highly waterproof

- A very good impact absorber

- Ideal for workshops with heavy and vibrating equipment

- Protects subfloors from any hard and heavy falling objects

- Waterproof

- Slip-resistant

- Durable and Resilient

- Workshop Rubber tiles can withstand different temperatures

- Workshop rubber tiles can last for a very long period

- Easy to clean and maintain

- Easy to install

Choosing the Right Flooring for Your Workshop: Durability, Maintenance and Style

Selecting the right workshop flooring involves considering these essential aspects:

- Durability: Opt for rubber mats or interlocking tiles that can withstand the rigors of workshop activities, including heavy machinery and chemical spills.

- Ease of Maintenance: Choose flooring that’s easy to clean and maintain to ensure it remains in top condition.

- Style: Select from a variety of designs to find a look that enhances the aesthetic of your workshop.

Our Rubber Interlocking Tiles are perfect for those looking for versatility and ease of installation, while Rubber Mats offer robustness and comfort underfoot.

Why is Rubber Matting the Best for Workshops?

- Protects the existing floors from any impact and chemicals

- Rubber matting is a very good anti-fatigue

- Protects both users and tools as it has high cushioning properties

- Rubber matting is easy to clean and they look neat, when properly installed; they have a very good finishing.

For more the best workshop floors, do not hesitate to get in touch with our team

To purchase products online, click here.

#WorkshopFlooringSA #DIYProjects #RobustDesigns #SouthAfricanWorkshops #FlooringSolutions